|

By Pantz These

are the relevant manual pages

|

Hi there. So your brave enough to attempt to change your Elan M100 cambelt.Its quite a frustrating job. The hardest bit for me was working out how to undo the bottom pulley nut. You either need to jam the fly wheel or jam the pulley itself. There probably are other ways of getting around this .But i opted for a straight forward option and made this tool to lock the pulley..Once i had loosened the nut the job took about 4 to 5 hours. When i was getting frustrated with it i just grabbed a coffee and surfed the net.Treat this as a guide and read pages Ec 16/17/18/19 of the Elan Workshop manual.I aim to improve this write up with input from others.The actual fitting of the belt is straightforward its the limited access that is the problem . If i managed the job i am quite sure you can too.

Obviously if you attempt your cambelt change i cannot be held responsible for any thing going wrong.

..

If you have not done this job before on this car allow all day and be pleased with your self if you do it quicker.Because after all theres no hurry and your going to be saving a lot of money.I used the standard jack on the jacking point .and a small trolley jack under the engine.

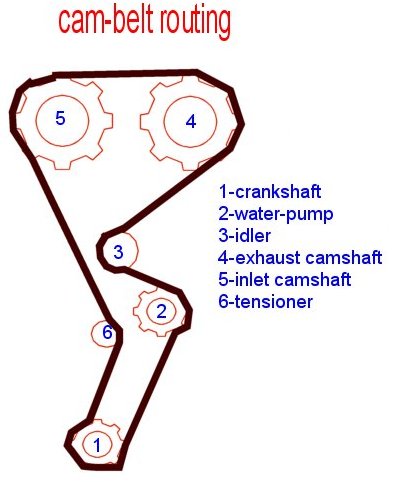

1:Loosen Right hand front wheel nuts./Position both jacks./Remove Wheel.

2:Remove bottom pulley 17mm socket you need to jam the pulley or the fly wheel to undo this nut.(if you cant undo this nut dont go any further).Lotus recomend setting the TDC before taking the pulley off. I did this slightly different because You are better to make sure you can get the pulley off before dismantling all of the engine mount/belts/camcovers.Because you would be quite sick if you spent a couple of hours undoing everything to find you cannot undo the bottom pulley nut..

3:Loosen Alternator belt and PAS.belt tensioners

4: Remove these two belts.

5:Take weight of engine with trolley jack.( used rubber mat on jack so not to damage sump) you shouldnt really jack the car up like this (because you can warp the sump .But as it was only taking the engine weight i went ahead as i couldnt see anywhere else to stick the jack).

6:Remove Right hand engine mount.Remove the bolt securing the engine bracket to the right hand engine mounting rubber.Remove the four bolts securing this to the engine.

List Of Tools.

I am waiting for input here. As i completed this job over a year ago i am waiting for someone to remind me of all the socket and spanner sizes.

Roy from Croydon is crawling around under his S2 right now.

If you already Have.

Metric socket set

Metric spanner set.

Metric allen key set.

Metric spline set.

1 x Standard Lotus jack

1x Trolley Jack..........

Massive Swear Box..

You will have sufficient tools to complete the job.

7:Remove all Bolts on the cambelt covers

8: Make sure the engine is set at TDC. That is the two marks on the top pulleys facing each other.And use the long bolts from the cam cover to lock the two top pulleys.Dont worry if the engine is not at TDC. Just pop the bottom pulley on and rotate the engine this way.Dont be tempted to turn it by using the top pulley bolts.With the top pulleys locked you cannot make any mistakes and put all of the timing out

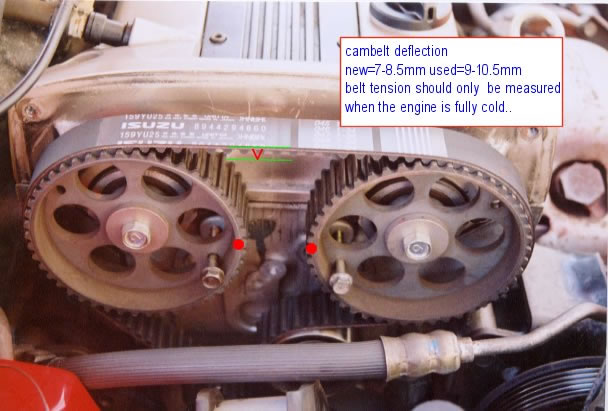

THIS PHOTOGRAPH SHOWS 1: THE CAMBELT DIRECTION 2: THE TDC(two red dots facing each other)3:HOW TO LOCK THE TOP PULLEYS IN A SAFE POSITION..4: THE TENSION THE BELT SHOULD BE ADJUSTED TO..

WARNINGS FROM THE LOTUS MANUAL.

Dont pry or stretch the belt with

a screwdriver or any other tool.

Dont force the belt to bend or twist excessively or damage may be caused to the belt core.

Dont get oil or any other chemicals on the belt.

Store cam-belt in a cool place dont expose to heat or direct sunlight .(suppose the engines a cool place to store it)

Dont rotate the crankshaft or the camshafts with the belt removed or damage may be caused to the valves and pistons.

Use your mouse to scroll over parts to get more

information